Manufacturing units

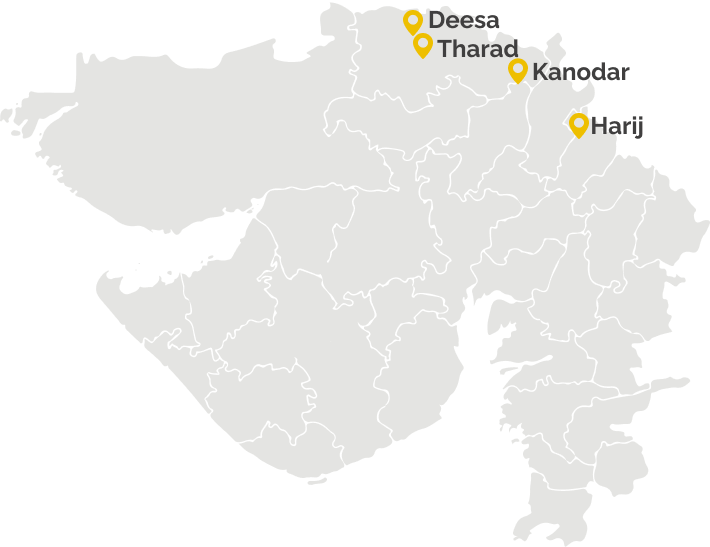

Rajgor Protein Limited has four state-of the-art manufacturing units spread over parts of Northern Gujarat.

Location: Kanodar

Capacity: 450 Metric Tons (MT) per day

Key Operation:

Crushing of Castor Seeds: The facility is dedicated to the extraction of oil from castor seeds, a major industrial crop known for its versatile applications.

Production Outputs:

- Castor Oil: The oil extracted is used in a variety of sectors, including pharmaceuticals, cosmetics, lubricants and chemicals.

- Castor De-Oiled Cake (DOC): A byproduct of the oil extraction process, the DOC is a high-protein substance primarily used in animal feed and as a natural fertilizer.

Strategic Location Benefits:

Positioned in the Castor Bowl of India, Gujarat

- Agricultural Advantage:

Being in proximity to extensive castor cultivation fields reduces logistics costs for raw material procurement and enhances the reliability of the supply chain. - Transport Connectivity:

- Road Access: The facility enjoys excellent road connectivity, providing easy access to national highways. This ensures smooth transportation of goods both within the region and to other parts of India.

- Rail Access: The presence of a robust rail network nearby facilitates efficient transportation of bulk raw materials and finished products, further enhancing the facility’s operational efficiency.

- Proximity to Mundra Port

- Export Efficiency: The facility is located near Mundra Port, one of the largest ports in India. This proximity is a significant advantage for export activities, reducing transit time and costs associated with shipping products to international markets.

- Logistical Advantage: The nearby port allows for rapid and efficient export of castor oil and DOC, which is crucial for maintaining a competitive edge in the global market.

- Quality Control: The in-house lab facility ensures stringent quality control measures for both raw materials and finished products.

This facility conducts comprehensive testing to meet international quality standards.

Location: Harij

Production Capacity: 50 Metric Tons (MT) per day

Key Operations:

- Crushing of Seeds:

- Groundnut Seed: The facility processes groundnut seeds, which are crushed to extract oil and produce de-oiled cake.

- Mustard Seed: The facility also crushes mustard seeds to extract mustard oil and produce mustard de-oiled cake.

Production Outputs:

- Groundnut Oil: A high-quality edible oil extracted from groundnut seeds, known for its flavor and high smoke point, making it ideal for cooking.

- Groundnut De-Oiled Cake (DOC): A byproduct rich in protein, used primarily as a livestock feed ingredient.

- Mustard Oil: An edible oil extracted from mustard seeds, valued for its pungent flavor and health benefits, commonly used in Indian cuisine.

- Mustard De-Oiled Cake (DOC): A protein-rich byproduct used as an animal feed supplement and organic fertilizer.

Seed Procurement Strategy

- Local Market Sourcing:

The facility sources groundnut and mustard seeds from local markets, ensuring a steady supply of raw materials. - Procurement from Agricultural Produce Market Committees (APMC): These are government-regulated markets where farmers bring their produce. Sourcing from APMC ensures the facility obtains seeds at competitive rates, directly supporting local agriculture.

- Direct Procurement from Farmers:

By purchasing directly from farmers, the facility establishes a reliable supply chain and fosters relationships with local growers, ensuring high-quality raw materials and supporting the local farming community.

Packaging Facility

The facility includes an on-site packaging unit capable of efficiently packaging oils in various formats, ranging from small retail bottles to bulk containers.

- Packaging Types:

- Retail Packaging: Suitable for consumer markets, ensuring that the oils reach customers in ready-to-use formats.

- Bulk Packaging: For wholesale and industrial clients, available in large containers that facilitate ease of transport and storage.

- Packaging Standards:

The packaging facility adheres to strict hygiene and safety standards, ensuring that the oils are packed in clean, food-grade containers, maintaining the quality and integrity of the products during storage and transportation.

FSSAI Certification: The facility is certified by the Food Safety and Standards Authority of India (FSSAI)

Location: Deesa, Banaskantha

Production capacity: 500 Metric Tons (MT) per day.

Key Operations:

- Crushing of seeds:

- Non-Edible Segment: Focused on crushing castor seeds.

- Edible Segment: Specializes in the crushing of groundnut (peanut) and mustard seeds.

Production Outputs:

- Castor Oil: Used industrially in lubricants, coatings, and cosmetics.

- Castor De-oiled Cake (DOC): A by-product used in organic fertilizers and animal feed due to its high nitrogen content.

- Groundnut Oil: A popular cooking oil known for its flavor and stability at high temperatures.

- Groundnut DOC: Used in livestock feed because of its high protein content.

- Mustard Oil: Known for its pungent flavor and commonly used in cooking and pickling.

- Mustard DOC: Also used in animal feed and as an organic fertilizer.

Seed Procurement Strategy

- Advanced Machinery and Technology

- Machinery: The facility is equipped with state-of-the-art machinery for seed crushing and oil extraction.

- Technology Utilized: Likely includes cold pressing and expeller pressing techniques, which preserve the quality of the oils.

- In-house Laboratory: Ensures quality control and testing of the products to maintain industry standards and compliance with health regulations.

Logistics and Connectivity

- Road Connectivity: The facility benefits from good road connections, facilitating efficient transport of raw materials (seeds) and finished products.

- Procurement: Seeds are sourced from local Agricultural Produce Market Committees (APMCs).

Strategic Advantages

- Location Proximity: Being located near agricultural areas, the facility has easy access to raw materials, reducing transportation costs and ensuring a steady supply.

- Local Sourcing: Procurement from local APMCs supports the local economy and ensures freshness and quality of the seeds.

- Versatile Processing: The ability to process both edible and non-edible seeds makes the facility versatile and allows it to tap into diverse markets.

The facility's dual-segment operations allow it to cater to various sectors, including food, cosmetics, and industrial applications, thereby enhancing its market reach and sustainability.

Location: Tharad, Banaskantha

Production capacity: 100 Metric Tons (MT) per day.

Key Operations:

- Cleaning:

The facility is equipped to thoroughly clean various agricultural products to remove impurities, dirt and foreign particles. - Sortex (Sorting and Grading):

Utilizes advanced optical sorting technology to sort and grade the products based on size, color, and quality. This ensures consistency in product quality and enhances market value. - Packing:

The cleaned and sorted products are packed efficiently, maintaining hygiene and quality standards, and are prepared for distribution.

Production outputs

- Spices: Including, but not limited to, turmeric, coriander, cumin, and chili.

- Pulses: Such as chickpeas, lentils, and green gram.

- Wheat: Primarily for flour production.

- Dals: Different varieties including toor dal, urad dal, and moong dal.

Infrastructure and Machinery

The facility is equipped with the latest technology in cleaning, sorting, and packing, ensuring high efficiency and quality.

- Cleaning Machines: Equipped with air and vibratory cleaning technology to remove dust, stones, and other impurities.

- Sortex Machines: State-of-the-art optical sorters that utilize cameras and sensors to detect and remove defective grains and foreign materials.

- Packing Machines: Automated systems for filling, sealing, and labeling, which minimize manual handling and enhance packaging quality.

Strategic Advantages

- Location Benefits:

Proximity to APMC Market Yard:

Located near the APMC Market Yard Gate No. 3 in Tharad, Banaskantha, providing easy access to fresh and diverse agricultural produce.Ensures efficient procurement and quick turnaround times for raw materials.

- Connectivity:

Situated on Sanchor Highway, which ensures seamless connectivity for transportation and logistics.

Facilitates quick distribution to regional and national markets.

- Procurement from Local APMC:

Engages with local farmers and traders through the Agricultural Produce Market Committee (APMC), ensuring a steady supply of quality raw materials.

Supports local agriculture and promotes sustainable sourcing practices.

- Market Reach:

With advanced processing capabilities, the facility can cater to both domestic and international markets, meeting various quality standards and consumer preferences.

The strategic location and high capacity enable competitive pricing and reliable supply chains.